Wire rope operation precautions

1. Incoming acceptance of wire rope

For all wire ropes, proper maintenance and management must be carried out immediately after acceptance. After the wire rope arrives, it is necessary to carefully check whether the cargo specification matches the label and the manifest on the package. Keep the wire rope in a place where wind and rain are not invaded. The environment is dry but the temperature cannot be too high. When the wire rope is assembled on the equipment, it is often oiled on the surface of the wire rope to prevent rust, reduce friction and prolong service life.

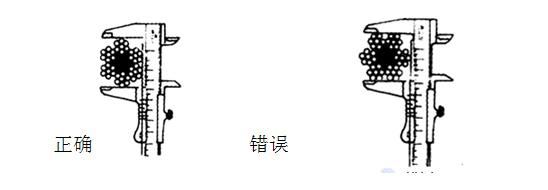

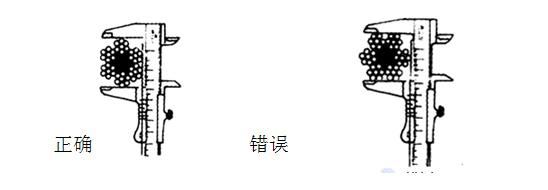

Wire rope diameter measurement method:

2. Installation and commissioning of wire rope

Equipment and facilities: Install galvanized, smooth steel wire ropes should have a rope-removing machine (or unwinding frame), a shaft, and should also have a chuck for the rope head, generally designed as a U-bolt and a punch-grip chuck. In addition, there should be basic equipment such as take-up reels.

Installation procedure: check the rope diameter → release the rope → fix the rope head → wind the wire rope on the reel

3. Rope method

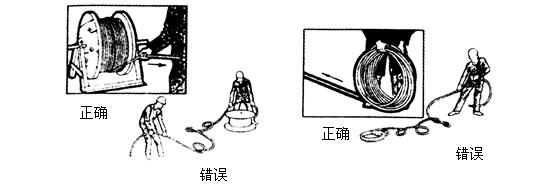

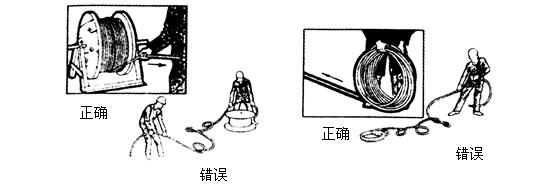

For ropes with sheaves, the ropes should be placed on a bracket that allows the sheave to rotate while the rope is being laid, and then the ends of the ropes are led to extend straight.

For wire rope coils without a sheave, the rope should be rolled up during the rope release and rolled straight in the opposite direction of the end of the rope to achieve the purpose of rope release. Be careful when handling to avoid the rope forming a knot. The steel wire formed by the rope produces permanent deformation and sprain, which affects the service life of the wire rope. Take care when releasing the rope with the same 捻 捻 wire rope to prevent kinks from hurting people.

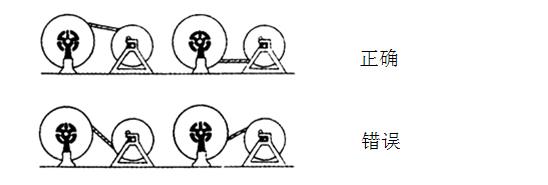

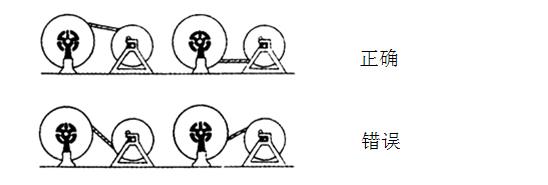

Heavy roll, minute wheel

When it is necessary to roll the wire rope from the factory-supplied reel to the reel of the equipment (or another smaller reel), the best way is to "go in and out" or "down and down", so that It can be avoided that the wire rope is installed on the equipment under reverse bending, otherwise the rope body will be unstable and difficult to operate.

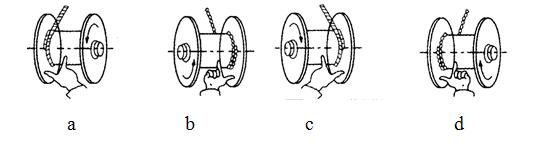

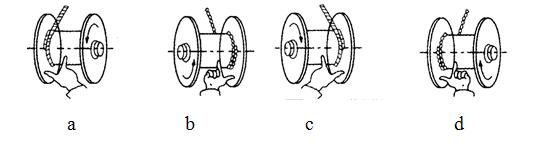

4. Winding direction of the wire rope on the reel

The direction in which the left and right twisted wire ropes are wound on the reel must be wound in a direction in which the wire rope is tight rather than loose. The wire rope of the right 捻 (Z), if the reel rotates from top to bottom, the wire rope should be arranged from left to right (as shown in Figure a). If the reel rotates from bottom to top, the wire rope should be arranged from right to left (as shown in the figure). b); in contrast to the left 捻 (S) wire rope, the direction of the wire rope on the drum shall be as shown in Figure (c) and Figure (d).

5. Precautions when loading the rope

When the multi-strand steel wire rope or the elliptical strand steel wire rope is roped, the rope end should be prevented from being loose. If there is looseness (the distance between the turns becomes larger), the end of the rope should be properly energized so that it can be caught in the winch drum after the original state, so as to eliminate the phenomenon of "lantern" in the running of the rope.

6. Wire rope maintenance and repair

Daily maintenance and maintenance: Always keep the surface of the wire rope clean, and the adherend should be cleaned in time to prevent broken wire due to the change of the performance of the wire rope caused by severe friction; the wire rope should be regularly injected (coated) according to the conditions of use to prevent corrosion.

Maintenance and maintenance during long-term parking: The long-term parking wire rope should be rolled 180 degrees (turn over) every six months to prevent grease from dripping. It is forbidden to rub the grease on the wire rope with rags and fingers to prevent rust.

Maintenance and maintenance of the wire rope during operation: According to the regulations, on time inspection, close to the replacement period, if it is found that the fatigue broken wire develops rapidly or there is abnormal condition, the inspection cycle should be shortened.

7. Wire rope lifting and transportation precautions and storage conditions

Lifting transportation precautions:

A When loading and unloading large coils of steel wire rope, be sure to insert the steel shaft into the central shaft hole of the wooden disc, and hang the lifting rope at both ends of the steel shaft to slowly hoist. It is strictly forbidden to insert the hoisting rope into the central shaft hole of the wooden plate to avoid damage to the wire rope.

B The steel wire rope is sealed with a tarpaulin during the middle operation to prevent moisture.

Wire rope storage conditions:

The wire rope should be stored in a dry and ventilated warehouse with an upper cover and a lower pad. Open storage is prohibited. Wire ropes in the warehouse cannot be stacked in multiple layers. Wire ropes without guards are not allowed to roll on the ground to prevent contamination of gravel and abrasion of steel wire.

8. Wire rope use, safety protection and precautions during operation

A preparation and inspection before use

Before using the wire rope, check that it has been installed in the correct procedure as described in this manual and that the head is properly attached and secured to the drum. The entire system should be carefully started and run at a very low speed for one cycle (referring to one lift to drop process, one pull in position and reset process, etc.). In this idling operation, the sheave, reel and drum should be checked very carefully. The second step is to add a low load and run a few more cycles at a lower speed to gradually adapt the various parts of the wire rope to the actual operating conditions.

B Safety protection.

In use, the hoisting wire rope must be inspected once a day, and the balance wire rope and the wellbore suspension wire rope are inspected at least once a week. A detailed inspection of the section that is vulnerable to damage and broken or rusted should be carried out.

In use, there must be a strict oiling system and oiling facilities. Apply oil to the wire rope in use at least once a month.

Precautions during the operation of C wire rope

1 In normal operation, the wire rope is in contact with the rope reel, drum and plate, all of which must be carefully maintained and in good condition.

2 running monitoring and recording

All parts that come into contact with the wire rope, such as the sheave, the reel and the wire rope itself, must be inspected regularly.

3 When checking the sheave and reel, first check the condition of the rope groove. A circular groove radius gauge is usually used to check the shape, size and wear of the groove section.

4 The bearings of the sheave and the drum must also be inspected. If the movement is not flexible, the lubricant should be injected.

5 The steel rope itself must be regularly checked for rope diameter reduction, broken wire, wire wear, etc., and records should be made. When the scrap conditions specified in the safety regulations are met, the steel rope must be scrapped.

9. Fault analysis and elimination of wire ropere rope / maximum static tension of the wire rope.

10. Calculation method of safety factorWire ropes are subjected to various loads during operation, but the sum of all these loads must not exceed the minimum breaking force of the wire rope, and in order to ensure reliability and safety, depending on the importance of its use in different occasions Also, there must be a large safety factor corresponding to it.Wire rope safety factor = minimum breaking force of the wire rope / maximum static tension of the wire rope.